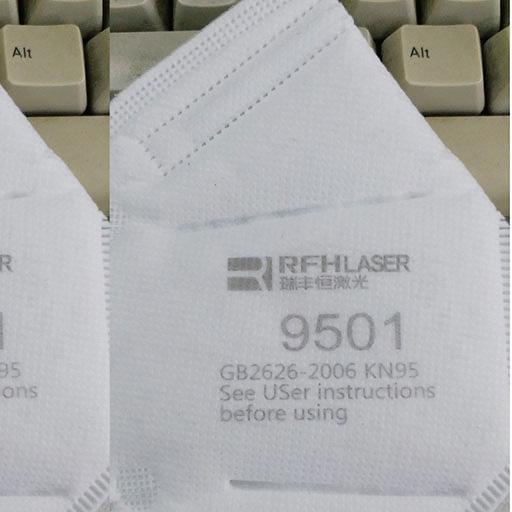

Nanosecond UV laser marking production date of yogurt packaging box

Marking the packaging box production date, RFH UV laser is fast

Nanosecond UV laser marking the production date of yogurt packaging box without burning

Yogurt has the effects of preventing high blood pressure and high blood lipids, reducing the risk of colon cancer, as well as beautifying, nourishing the skin, fixing teeth, and nourishing hair. A yogurt after a meal is delicious and relieved. The shelf life of yogurt is from 18 days to 21 days. Each yogurt box has a production date marked by UV laser. Please remember, buy food with UV laser marking on the package.

why?

Marking on food packaging can be done in two ways: ink jet coding and ultraviolet laser marking.

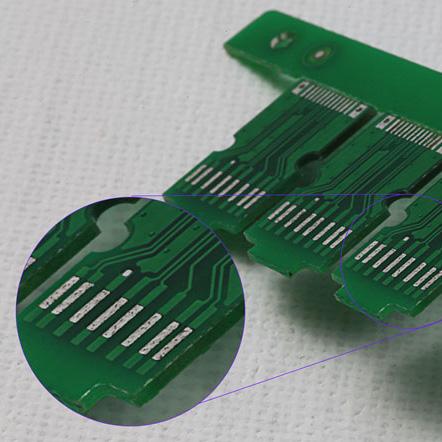

The traditional ink jet coding process can forge or change the production date on the packaging bag. It is easy to be forged or tampered with by illegal businesses, smeared, changed production date, and expired food is pushed to the market again to deceive consumers. UV laser marking technology is used for plastic marking. This type of laser etching technology can play an important role in identifying the authenticity of signs.

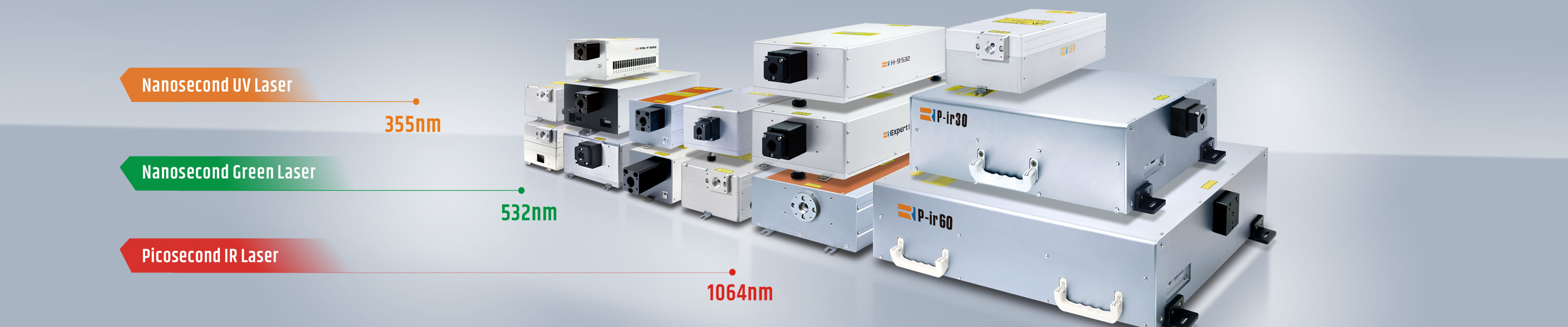

For marking the production date of yogurt boxes, RFH Expert Ⅱ 355nm UV laser is recommended. This model has a spot ellipticity >90%, pulse width <20ns@30k, small heat-affected area, and beam quality M2<1.2 in all frequency ranges All are strictly guaranteed, so when the production date is marked on the yogurt box, the material will not be burnt, and the yield rate is guaranteed.

In addition, the core components of its pump and Q switch are imported brands, and the parts cooperate with domestic first-line brand suppliers. From the source of the material procurement ecological chain, ensure the quality of each component. Moreover, the assembly process (the whole dust-free workshop), finished product testing, warehousing quality inspection, and pre-delivery inspection all have a rigorous quality management system mechanism, which is checked at all levels.

Therefore, comparing the materials and parameters, the RFH UV laser marking is obviously more stable.

Of course, its value does not stop there.

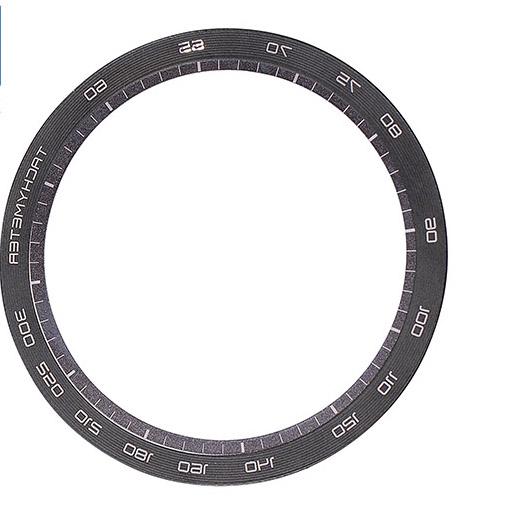

The Expert Ⅱ 355nm UV laser also has a fully digital intelligent power control technology independently developed by the RFH PhD R&D team, which can update the power control system function modules in time, and improve the function modules according to laser requirements; it has an internal cavity self-purification system to make the laser Long life, stable operation; integrated design, convenient equipment integration; with unique Q-switching control technology, suitable for various laser application control needs, with it, the laser marking business is so easy to expand, and the production date of the instant noodle plastic packaging bag is marked Targeting is just one of your high-efficiency businesses.

12 лет напряженной работы RFH были не только удовлетворены производством высококачественных лазеров, мы также запустили полный план продаж системы для источника питания + лазер + система охлаждения с точки зрения пользователей, чтобы обеспечить стабильность всей лазерной системы и его лучшее исполнение. Благодаря этому мы завоевали высокое признание и хорошую репутацию среди пользователей во всех сферах жизни в стране и за рубежом, а также создали отличный имидж бренда в индустрии наносекундных лазеров.