Для лазерного кодирования пластиковых бутылок используется ультрафиолетовый лазер S9, дата кодирования не может быть стерта

УФ-лазер S9 для упаковки пищевых продуктов, упаковки пластиковых бутылок, кодирования

УФ-лазер S9 отмечает дату на пластиковых бутылках для напитков

После еды приходите на молочнокислый бактериальный напиток Wahaha, чтобы снять сальность и очистить желудок, что является привычкой многих детей.

Здоровый образ жизни и правильное питание стали шкалой жизни людей. Каждая бутылка молочнокислого бактериального напитка Wahaha будет маркирована датой производства, которая наносится УФ-лазером и не стирается, что полностью исключает мошенничество со стороны нелегального бизнеса.

Что такое УФ-лазерная маркировка?

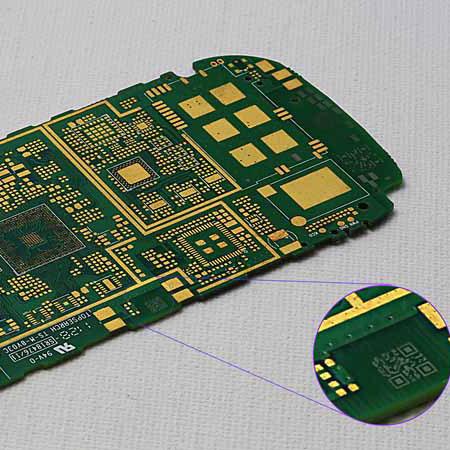

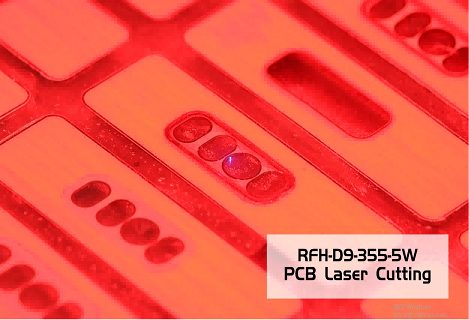

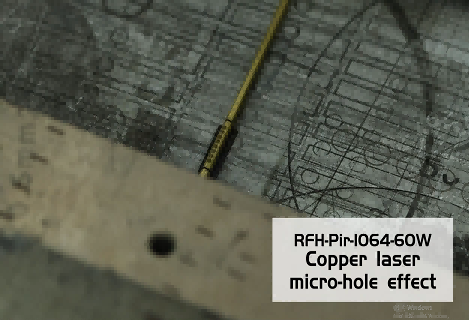

Laser technology is used for non-contact marking on the surface of the material. Because it is not affected by mechanical movement, the surface will not be deformed, and it is not affected by the elasticity and flexibility of the material, which is convenient for processing and engraving on soft materials. With high processing precision and fast speed, it is widely used in 3C electronics industry, food carton packaging, plastic packaging, glass materials and other fields.

UV laser marking, environmental protection, energy saving, pollution-free, does not contain any toxic substances, easy to pass the RoHS standard, easy to produce.

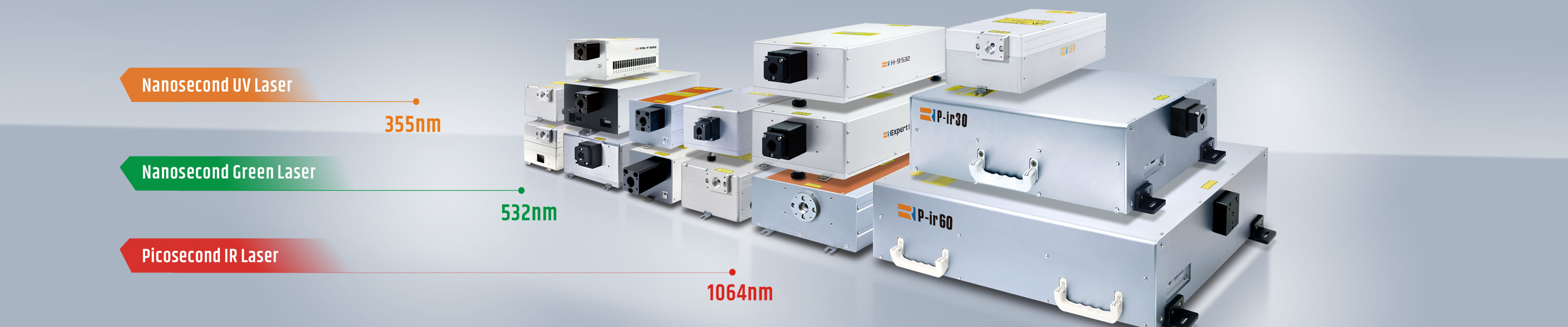

The following recommended editor strongly recommends a UV laser with high technical gold content and beautiful appearance design to you, not to be missed.

According to market development needs, RFH's newly launched S9 series pulsed ultraviolet solid-state lasers in 2020 are smaller in size, more exquisite in design, and more stable in light output than similar products. The small and exquisite design means that users do not need to make a large optical path, which can greatly reduce costs, save space, and have good mobility. It is easy to install in the field of equipment such as flying marking. The S9 ultraviolet laser is not only compact, but also has a more stable cavity structure and stronger scalability than similar products. The same cavity can produce lasers of different powers, and the stability of different power ranges is greatly improved.

RFH UV laser S9 has stable quality and stronger competitiveness

Ultraviolet lasers usually output wavelengths below 0.4μm, which is the main advantage of processing polymer materials. Unlike infrared processing, ultraviolet micro-processing is not essentially a heat treatment, and most materials absorb ultraviolet light more easily than infrared light. The short wavelength of ultraviolet itself has advantages for the mechanical micro-processing of metals and polymers. It can be focused to a point on the order of sub-micrometers, so it is widely used in the processing of fine parts.

For machine manufacturers, a good solid-state laser can effectively improve production efficiency and provide terminal equipment with stronger market competitiveness. The new product series of RFH pulsed ultraviolet solid-state laser S9 has a laser wavelength of 354.7nm and a wide range of repetition frequency (single pulse to 200kHz), which can be absorbed by the material and is less destructive to the material. And it has superior beam quality (M2<1.2), which is strictly guaranteed in all frequency ranges; pulse width is <20ns@30k, and the heat-affected area is small during processing.

RFH UV laser S9 has full digital intelligent control function

S9 series UV lasers also have unique Q-switching control technology, full digital intelligent power control, simple operation, low cost of hands-on, and suitable for various laser application control needs; the internal cavity self-purification system makes the laser long life, stable operation, and low Maintenance costs. We fully consider the convenience of machine control in the workshop, so the laser also supports communication with the computer, and the laser can be controlled externally through RS232.

Seiko 13 years of research and development by RFH, each laser product produced can maintain consistent stable quality, constant beam quality, high-efficiency power consumption under extreme industrial and scientific research conditions, and win with excellent cost performance and high reliability Highly recognized by users in all walks of life at home and abroad and a good reputation.