What can UV lasers mark

The stable quality of RFH 355nm UV laser comes from strict control of every detail

Ultraviolet laser heat affected area is very small, no heat effect

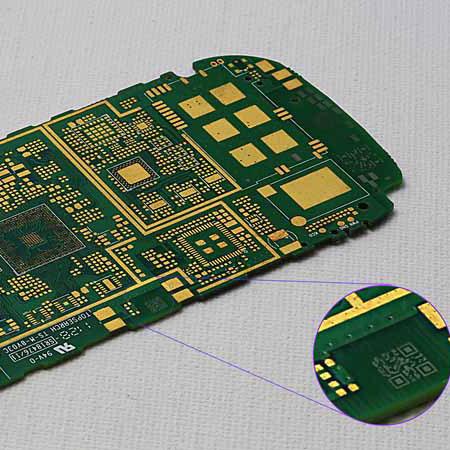

This issue of RFH Laser Industry Online Tea Conference is a bit embarrassing. The topic of this issue is, what can UV lasers mark? As we all know, the UV laser marking machine is one of the three major killers in industrial manufacturing (the other two are laser cutting and laser welding), and it is applied to too many industries, plastic, glass, acrylic, ceramic, crystal , Jade, countless. In the case of smart devices, UV laser marking technology is applied to multiple components such as the outer casing, buttons, internal PCB circuit boards, and batteries.

Although the RFH Laser Editor does not know how many things can be marked by UV lasers, I know that these things have one thing in common, that is, the requirements for laser beams are very high. How high are the requirements? Let me listen to the editor slowly.

Laser marking, mainly some text, LOGO, two-dimensional code, production date, serial number, pattern, ultraviolet laser, fiber laser, CO2 laser are all available, but if you want to process these effects on these materials, then only It can be an ultraviolet laser, because the ultraviolet laser has a small thermally affected area, no thermal effect, and no scorching of the material. If you use the other two lasers, it will not be marking, but will burn.

Finally, the editor recommends a high-quality UV laser, RFH Expert Ⅱ 355nm UV laser, which is highly recognized by users from all walks of life at home and abroad and has a good reputation.

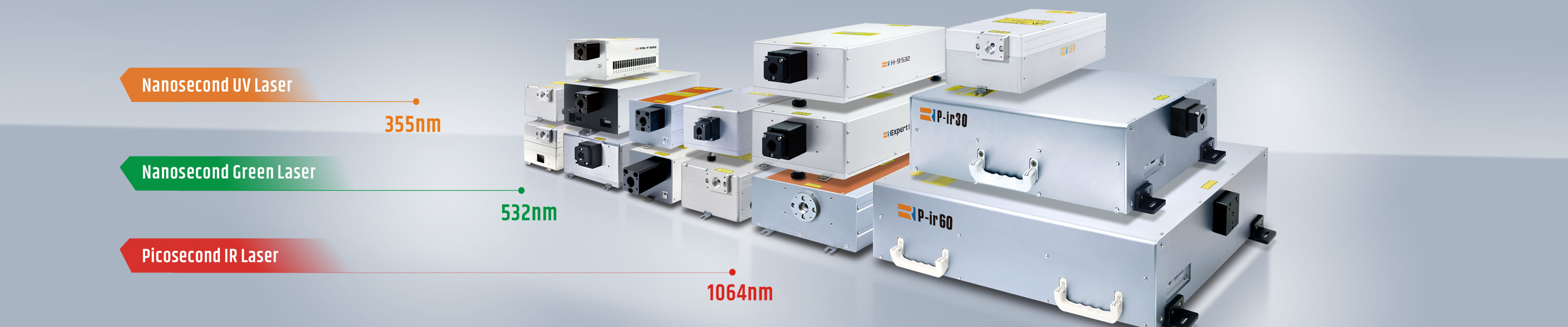

RFH Expert Ⅱ 355nm UV laser has fast marking speed and high efficiency (thanks to its short pulse width (<14ns@30K), superior beam quality (M2<1.2) and perfect spot characteristics (spot ellipticity>) 90%), able to maintain consistent and stable quality under extreme conditions in industry and scientific research)

The superior quality of this UV laser is due to RFH Laser’s R&D technology and rigorous production management system:

With a doctoral level R&D team as a solid technical backing, with self-developed fully digital intelligent power control technology, it can update the power control system functional modules in time, and improve the functional modules according to laser requirements to ensure stable performance; unique Q-adjustment control The technology makes it suitable for various laser application control needs, and the internal cavity self-purification system makes it long and durable.

На производстве каждая деталь строго контролируется. От закупки, предпроизводственного контроля качества до процесса сборки, тестирования готовой продукции, контроля качества на складе и перед поставкой — каждый уровень проверяется для обеспечения стабильного качества и соответствия параметров оборудования фактическим рабочим параметрам. Это тоже одна из причин, почему срок службы лазеров марки RFH лучше, чем у аналогов.

12 лет глубокого развития бренда, так что ультрафиолетовый лазер RFH был рекомендован пользователями.