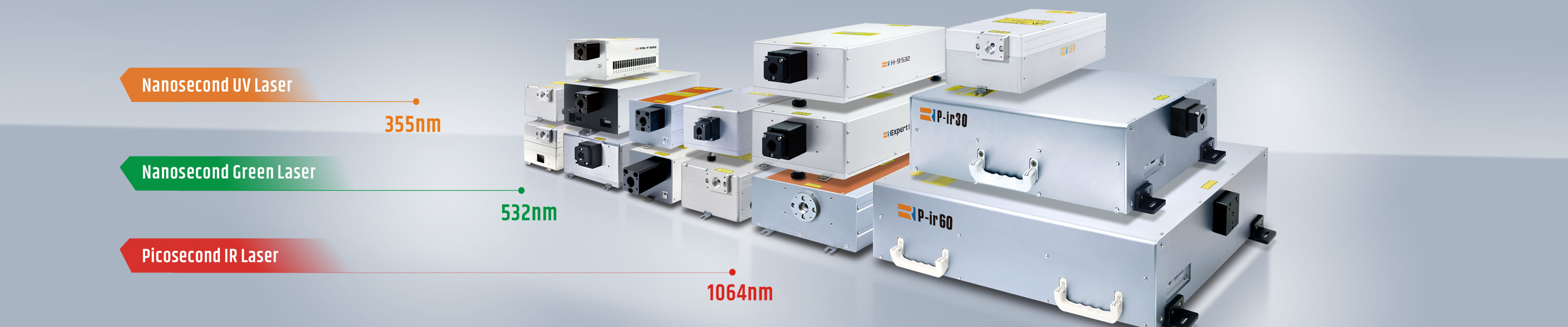

What is Solid State 3 W Air Cooled DPSS UV Laser

UV Laser is a laser with the short wavelength 355nm to generate an intense energy beam breaking the molecular bonds and vaporize the substrate leaving a permanent mark without contacting the substrate. It is very suitable for sensitive and critical material(such as plastic , leather, etc.) marking with the advantage of its "cold marking" methods. Because it offers a higher absorption rate than fiber and CO2 lasers and are less likely to burn the surrounding material because they produce less heat. This is why UV laser is also referred to as “cold processing method”, while fiber and CO2 lasers are called as ‘thermal processing method’. Fiber / CO2 laser marking machine can alter or even burn some heat-sensitive materials, like plastic, leather, etc. This is because the laser energy is not fully absorbed, allowing too much light to pass through without marking the material. You’re left with indecipherable logos, unreadable barcodes, or damaged parts.

3. Product Application

1) UV Laser SLA 3D Printing Samples

SLA 3D Printer use 355nm UV laser light to cure light-reactive thermoset resin into hardened plastic. When SLA resins are exposed to UV laser light, short molecular chains join together, polymerizing monomers and oligomers into solidified rigid or flexible geometries.

2) UV laser can apply to most universal plastic and some engineering plastics, such as PP, PE, PBT, PET, PA, ABS, POM, PS, PC, PUS, EVA, etc., and plastic alloy, like PC/ABS and other material. The marking is clear and bright, and can mark black and white color on natural color plastic, white plastic, colored plastic and black plastic. Successful commercialized application in the plastics include animal ear tag, light switch cover, cosmetic packaging material, vehicle interior button and doorknob, instrument panel, ABS keyboard, HDPE, PET and PVC rigid container and container cover, nylon and PBT automobile and non-automobile electrical connector, engine hood element such as fuse box and air cap, anti-counterfeit labels, container lock catch, stationery, home appliance shell, etc.

3) обработка стеклянных материалов

Поскольку фокусное пятно УФ-лазера очень маленькое, а температура обработки низкая, кроме того, как технология бесконтактной маркировки, УФ-лазер очень подходит для маркировки стеклянных материалов. Успешные коммерческие применения УФ-лазера включают винные бутылки, бутылочки для ароматизаторов, бутылки для напитков и другие отрасли промышленности, упаковку стеклянных бутылок и стеклянную посуду, подарки из стекла, маркировку кристаллов и т. д. Помимо непосредственной маркировки стекла, УФ-лазер также может удалять краску или покрытие на стекле для формирования текст или узор, например логотип, номер или другие узоры;